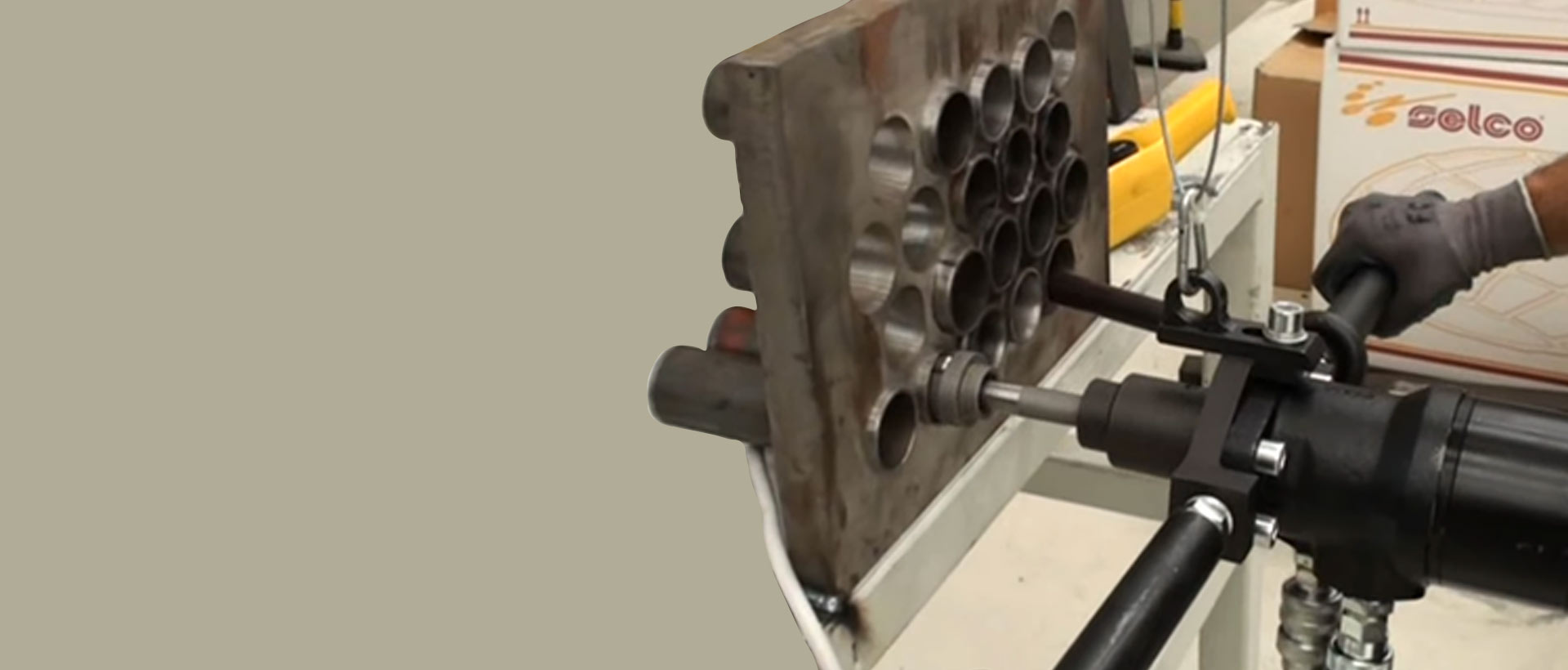

Condenser, Heat Exchanger, Boiler Manufacturing OR fabrication unit's needs tubes to be fixed inside tube sheet and shell for the same process Tube expansion is needed. Also repairing of puncture or damaged tubes after tube replacement, same tube requires tube expansion process like electric, pneumatic OR hydraulic.

Tube expansion helps in sorting problems encountered in shell and tube type heat exchangers. Tube expansion methods involve expanding the tube inside the tube sheet and swaging to ensure that the space between the two components is always forced closed. Electric, Pneumatic OR Hydraulic expansion is the direct application of high internal pressure within a tube or sleeve in order to form a tight joint between the tube and the tube sheet, or a tight seal between the sleeve and the tube.

After the Tube Expansion process all tubes are checked with the pressure to find all tubes are properly expanded.